OberonTouch

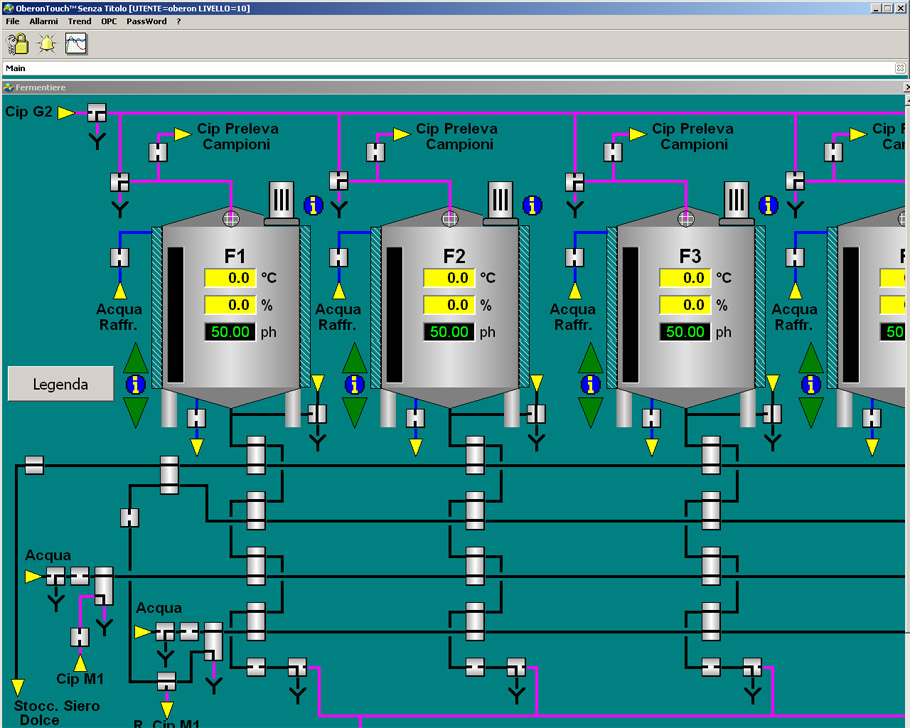

Result of decades of experience acquired on your plants. Simplicity of use, performances and scalability are the characterizing elements; based on a graphical windows interface, it allows you to open your systems to more flexible and advanced HMI and traceability technologies.

A solution dedicated to industrial process supervision applications that is effectively adapted to both small plants and complex applications with the same ease of use.

Oberon.Soft

Oberon.Soft deals with the development of software in the industrial field and in particular in the agri-food and pharmaceutical sector.

Oberon.Soft has achieved good national and international competence in the development of control and supervision software for industrial plants, using standard systems such as Siemens PLC, and proprietary systems such as APV Accos and Intelligent Integrator. He is able to develop the control software using the Paracode Apv programming language, and the most common languages.

Oberon.Soft has also created a program package called OberonTouch, which allows us to offer our customers a supervision and traceability management system aimed at solving the main process control problems. Oberon.Soft has the flexibility to meet the needs of each customer.

Products

OberonTouch

Builder

It is the IDE (Integrated Development Environment) for the creation of graphic pages, the configuration of OPC connections, alarms, messages, historical trends.

It has a scripting language that allows access to all the properties of the various components present in the form and also integrates a debugger for programming errors.

It consists mainly of the Project Manager containing all the forms of the project, from the Object Inspector for setting and displaying the parameters of the various objects present in the form, from the designer window to visually create graphic pages and from the script editor and debugger. It also has a component library to solve the main tasks of a supervision system.

OberonTouch

Runtime

It is the software that allows you to run applications created with the OberonTouch Builder.

Its task is to start the project and to communicate with the control devices such as PLC or DCS using the OPC (Ole for Process Control) standard, to view the various graphic pages and to execute the related scripts.

The runtime system supports all OPC Servers DA (data access) V1.0 /2.0/3.0 both locally and remotely and the OPC Server Xml DA for connection using the Soap Xml protocol. The runtime system as well as being able to connect with all the OPC Servers of the main manufacturers of automation and control devices in the world, allows connection with the DCS APV Accos30 and Intelligent Integrator systems through the use of a specific OPC Server, developed by us .

The Runtime has different license sizes depending on the number of tags to be managed.

OberonTouch

Trend

It is the software that allows you to view and archive historical trends.

It acquires the process variables from the system, displays the graph of the trend over time and stores the values. Historical trends can be retrieved and exported as an Excel file.

It also allows you to print the related trends in color with the various measurement scales, which are configured using the OberonTouch Builder development system.

OberonTouch

Alarm Server

It is the software that acquires all the alarms, messages and events that occur in the system, storing this information in a SQLite client / server database. The data can then be viewed and filtered using the specific page integrated in the OberonTouch Runtime system.

The configuration of alarm tags and messages takes place via the OberonTouch Builder development system. Alarms can be accessed remotely by simply indicating the server's IP address.

OberonTouch

Runtime VirtualUI

The OberonTouch applications can also be launched in Web mode. With this option the HMI is performed directly in an Internet Explorer browser, Google Chrome, Mozilla Firefox with the same functionality as the version for Windows operating systems. In this case it is not necessary to install OberonTouch on remote devices, which can be of any type such as PC Windows, Macintosh, IOS or Android tablet, Smartphone etc.

This technology uses a PC server with the Windows 10 Pro operating system, the Thinfinity VirtualU server, and the OberonTouch 4.0 VirtualUI version. The graphic pages are drawn directly in the browser through the HTML 5 Standard.

OberonTouch

Recipe Server

It is the software that allows you to manage the production recipes of the plants. The data is acquired by the control systems and saved in a SQLite client / server database. Later they can be extracted from the database and sent to the control systems to be executed. The recipes are configured through the OberonTouch Builder development environment.

It is possible to access recipe data remotely simply by indicating the IP address of the server.

AddOn

OberonTouch

Accos OPC Server

It is the software that allows the acquisition of all process variables (flags, registers, files, etc.) from the APV Accos30 and Intelligent Integrator control systems, via a TCP / IP connection and the OPC industrial communication standard.

Allows the addressing of variables in absolute or symbolic format.

Requires APV Accos IP software to work.

Multiple OPC clients can be simultaneously connected to the Accos OPC Server, both locally and remotely. Thanks to the Accos OPC Server it is now possible to connect any Scada that supports the OPC standard to APV control systems in a simple and safe way.

OBERONTOUCH IN THE WORLD

Trials

Download OberonTouch 4.0

The software supports the following Microsoft operating systems: from Windows 2000 Professional Sp6 to Windows11 Pro.

Partners

Contact Us

info@oberonsoft.com

ADMINISTRATION

stefano@oberonsoft.com

PUBLIC RELATIONS

stefano@oberonsoft.com

info@oberonsoft.com

info@oberonsoft.com